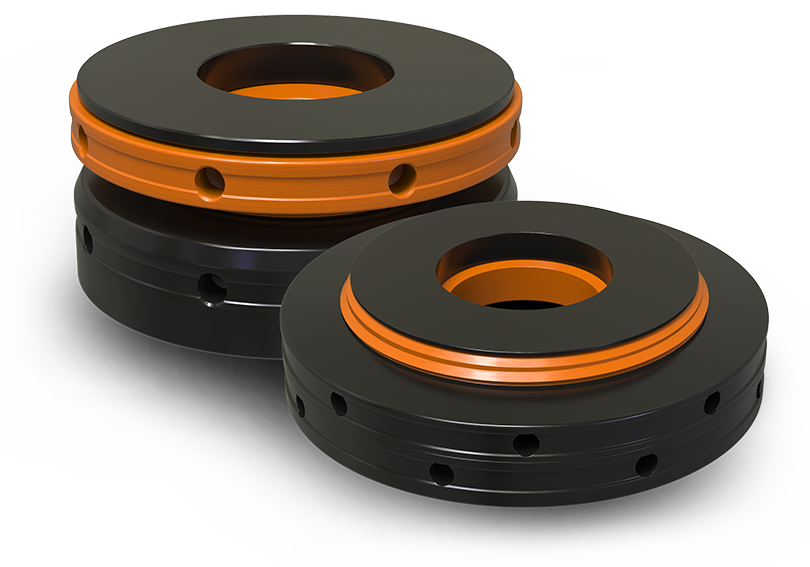

RotaChock® is an adjustable, self-levelling, reusable chock for mounting rotating equipment.

Ideal for large machinery and engines that need optimal alignment and to eliminate machinery soft-foot, RotaChock® is a robust interface between the foundation and machine foot.

How it works

RotaChock® allows for infinite height adjustment within the range of travel and is self-aligning – this means there’s no need to machine the subframe of the foundation.

This allows the alignment, foundation bolt tensioning and operation of the equipment or vessel to be completed within a day as it eliminates the curing time associated with resin chocks.

Used in diverse industries, including mining, oil and gas, marine, power generation and infrastructure, RotaChock® has several benefits, including:

Fast & easy installation

- A RotaChock® can generally be realigned and secured within a day, whereas epoxy resin chocks take at least three days for the machinery to function again, due to the resin’s relatively long curing time. Making traditional steel filler elements takes even longer, and labour cost makes it fairly expensive.

Optimum contact surface

- RotaChock® has a spherical bearing that ensures the best possible contact surface, even if the foundations and the machine foot aren’t parallel, and is height adjustable. The combination of these two features avoids “soft foot”, the situation where the foot of a machine or equipment doesn’t align to the base it is mounted on. Parallel soft foot and angular soft foot are the most frequent causes of poor alignment.

Any desired torque

- RotaChock®‘s behaviour is solid, which allows the foundation bolt to be tensioned to any required torque. Epoxy chocks, in contrast, have a maximum load of 3.5N/mm2, which often results in bolts being loosened.

High loads

- RotaChock® has a large footprint: as the surface area of the lower ring that is in contact with the foundation is greater, the pressure exerted on that surface is less. The RotaChock® also uses non-metric screw threading. Studies have shown that this allows the RotaChock® to handle 1.5 to 2 times greater loads. As a result of the reduced pressure at the surface and the higher loads, a chock with a smaller diameter than usual can be used.

Reusable

- The RotaChock® is reusable for the life cycle of your machine.

What size do you need?

While the rule of thumb solution is to select a RotaChock® based upon bolt size, for many applications technically sound and better economic solutions can be offered. To ensure you select the optimal size, ESI Tech Group can help.

ESI-Alphatec is an Australian distributor for RotaChock® and has a range of tall line, slim line, base line and hex line RotaChock® products.

These sizes, in various quantities, are available ex stock in Perth:

- RC-2

- RC-3

- RC-4

- RC-4.5

- RC-5

- RC-7

A range of stainless steel (316L) adjusting tools are available for each RotaChock® size.

RotaChock® has Type Approvals with:

- Det Norske

- Bureau Veritas

- American Bureau of Shipping Lloyds Register

- Germanischer Lloyd

- China Classification Society

For more information about RotaChock® and its applications, email info@esi-techgroup.com.